From Automation to AI: How Industrial Tech is Shaping the Future

The Evolution of Industrial Technology – From Mechanization to Intelligent Systems

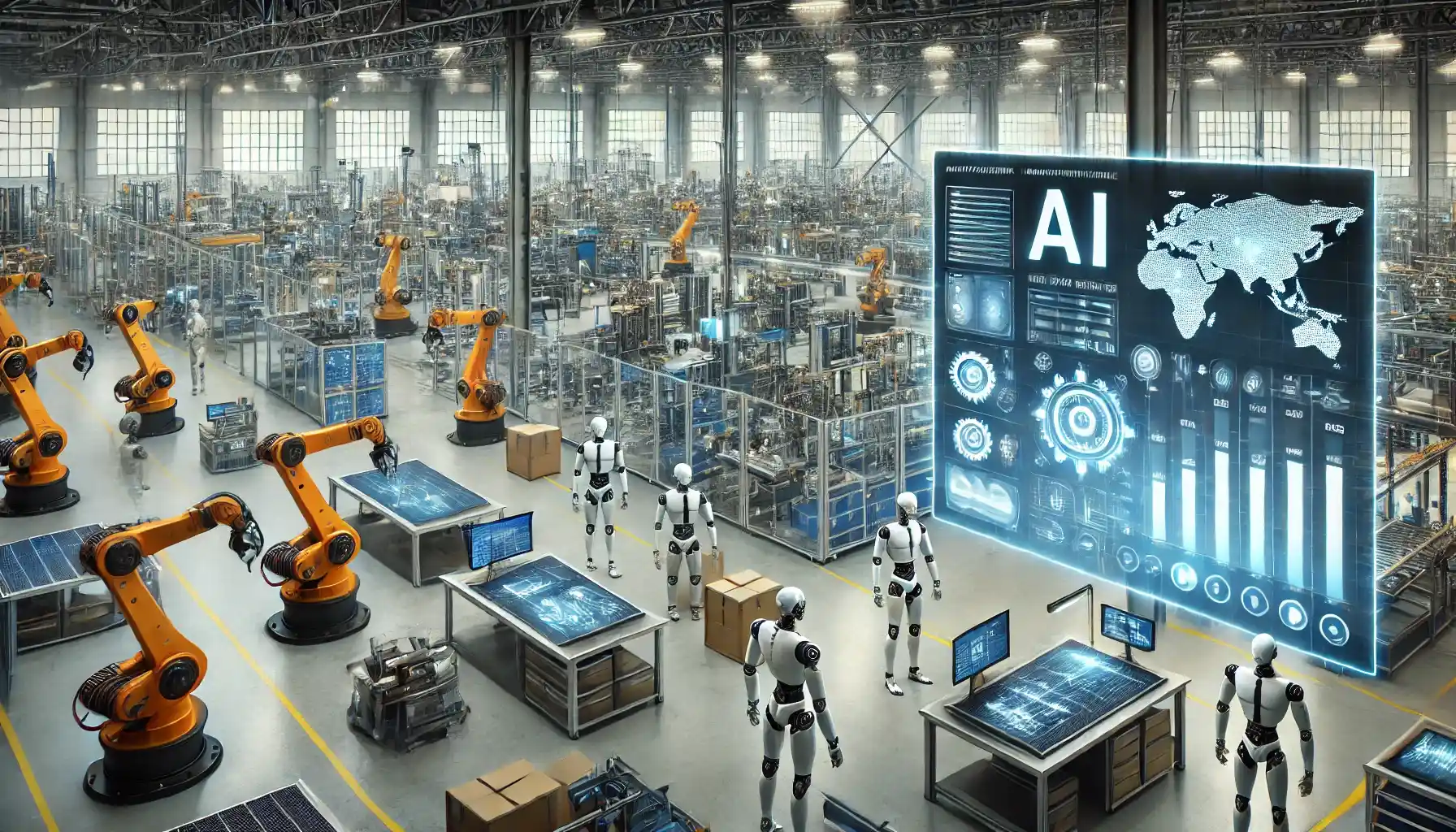

Industrial technology has seen significant transformations throughout history. Each revolution brought increased efficiency and innovation, from the mechanization of the first industrial revolution to the electrification of the second, and the digital revolution of the third. We now stand on the cusp of the fourth industrial revolution, an era defined by the integration of automation and artificial intelligence (AI). These technologies are creating smarter, more agile systems that are revolutionizing manufacturing.

The Rise of AI-Driven Automation

Automation has long been a cornerstone of industrial progress, but the incorporation of AI has propelled it to new heights. AI-driven automation involves the use of machine learning algorithms and data analytics to optimize processes, reduce downtime, and enhance overall efficiency.

Predictive Maintenance: One of the most impactful applications of AI in automation is predictive maintenance. By analyzing data from sensors embedded in machinery, AI algorithms can forecast potential failures before they occur. This capability minimizes unplanned downtime, reduces repair costs, and extends the lifespan of critical equipment.

Operational Efficiency: AI systems can process vast datasets to identify inefficiencies and recommend adjustments. For example, AI might detect bottlenecks in production lines or suggest energy-saving measures, resulting in more streamlined operations.

Real-Time Decision-Making: Traditional automation systems rely on pre-programmed instructions, while AI-driven systems can adapt in real-time based on changing conditions. This adaptability enables manufacturers to respond more effectively to disruptions or fluctuating demand.

AI is not just a tool for optimization—it’s a catalyst for innovation, enabling manufacturers to explore new possibilities in design, production, and logistics.

Collaborative Robotics (Cobots): The Human-Machine Partnership

The emergence of collaborative robots, or cobots, marks a significant shift in industrial automation. Unlike traditional robots designed to operate in isolation, cobots are built to work alongside human operators, creating a synergistic partnership that enhances productivity and safety.

Shared Workspaces: Cobots are equipped with advanced sensors and AI capabilities that allow them to navigate shared workspaces safely. They can detect and avoid obstacles, ensuring smooth interactions with human workers.

Task Optimization: By performing repetitive or physically demanding tasks, cobots free up human workers to focus on more complex and creative activities. This division of labor improves operational efficiency and job satisfaction.

Ease of Deployment: Cobots are often lightweight, flexible, and easy to program, making them accessible for small and medium-sized enterprises (SMEs). Their versatility allows them to be quickly reconfigured for different tasks, increasing their utility across various applications.

Industries ranging from automotive to electronics have embraced cobots for their ability to enhance agility and precision. As their capabilities continue to evolve, cobots will play a central role in shaping the future of industrial workplaces.

Augmented Reality (AR) and Virtual Reality (VR): Redefining Industrial Training and Maintenance

While automation and robotics focus on improving physical processes, augmented reality (AR) and virtual reality (VR) are transforming the human aspect of industrial operations. These technologies provide immersive, interactive tools for training, maintenance, and design.

Enhanced Training: AR and VR enable workers to gain hands-on experience in simulated environments. For example, VR can replicate complex machinery, allowing trainees to practice maintenance procedures without the risk of damaging equipment.

Maintenance and Troubleshooting: AR overlays digital information onto the physical world, guiding technicians through repair tasks step by step. This capability reduces errors, shortens repair times, and minimizes downtime.

Remote Collaboration: In a globalized industry, AR and VR allow teams to collaborate remotely. Engineers can use AR to visualize designs in real-world environments, while VR enables virtual meetings in shared 3D spaces.

These technologies are not just tools for efficiency—they are game-changers for worker empowerment, enabling employees to perform tasks with greater confidence and precision.

Additive Manufacturing: The Customization Revolution

Additive manufacturing, or 3D printing, has emerged as a revolutionary force in industrial production. Unlike conventional subtractive manufacturing methods that involve cutting away material, 3D printing builds components layer by layer based on digital designs. This approach offers unparalleled flexibility and efficiency.

Complex Geometries: Additive manufacturing allows for the creation of intricate designs that are impossible or expensive to achieve using traditional techniques. This capability is particularly beneficial in industries like aerospace, where lightweight and highly complex components are crucial.

Rapid Prototyping: 3D printing significantly reduces the time required for prototyping. Engineers can quickly produce and test multiple iterations of a design, speeding up product development cycles.

On-Demand Production: Additive manufacturing eliminates the need for large inventories by enabling on-demand production. This reduces storage costs and waste while allowing manufacturers to respond flexibly to market demands.

Customization: From personalized medical devices to bespoke consumer goods, 3D printing supports high levels of customization, catering to diverse customer needs.

Industries such as healthcare, automotive, and fashion are leveraging 3D printing to innovate and differentiate themselves in competitive markets.

Sustainable Manufacturing Practices: Redefining Industrial Responsibility

Sustainability is no longer optional in the industrial world—it is a necessity. Consumers, governments, and stakeholders are demanding environmentally responsible practices, and manufacturers are stepping up with innovative solutions.

Energy Efficiency: Smart factories are using IoT-enabled systems to monitor and optimize energy consumption. From smart lighting to energy-efficient machinery, manufacturers are reducing their carbon footprint without compromising productivity.

Circular Economy: The shift toward a circular economy emphasizes reusing, recycling, and repurposing materials. Additive manufacturing supports this model by enabling the use of recycled materials and reducing waste in production.

Sustainable Materials: Advanced research has led to the development of bio-based and biodegradable materials that meet performance standards while being eco-friendly. These materials are being adopted across industries to create greener products.

Water and Waste Management: Technologies such as IoT sensors and AI analytics are helping manufacturers monitor resource usage and reduce waste. For example, chemical plants are using AI to optimize water usage in production, ensuring minimal environmental impact.

Sustainability not only addresses environmental concerns but also delivers economic benefits by reducing operational costs and opening up new market opportunities for eco-conscious products.

The Interplay Between Technology and Sustainability

One of the most exciting developments in modern manufacturing is the synergy between technological advancements and sustainable practices.

IoT and Energy Management: IoT-enabled sensors provide real-time data on energy usage, helping factories identify inefficiencies and implement corrective measures. This integration reduces energy consumption and operational costs.

AI and Resource Optimization: AI algorithms analyze production data to optimize resource allocation, ensuring that materials and labor are used efficiently. This reduces waste and enhances overall productivity.

Additive Manufacturing for Sustainability: The ability of 3D printing to minimize material waste aligns perfectly with sustainability goals. Moreover, its capacity for decentralized production reduces the carbon footprint associated with transportation.

These innovations demonstrate that economic growth and environmental responsibility are not mutually exclusive. Instead, they can complement each other to create resilient, future-ready industrial systems.

Emerging Trends in Industrial Technology

The combination of additive manufacturing and sustainable practices is just the beginning. As industrial technology evolves, several trends are poised to redefine the industry further:

Smart Materials: The development of materials that can adapt to environmental conditions or self-heal is transforming sectors such as construction and healthcare.

Decentralized Production: Advances in 3D printing are enabling smaller, localized production hubs that reduce supply chain complexities and emissions.

Digital Twins: Virtual replicas of physical assets, known as digital twins, are becoming essential for simulating and optimizing production processes.

These trends highlight the limitless potential of industrial technology to innovate while addressing global challenges.

Opportunities in the Next Generation of Industrial Tech

The integration of advanced technologies into industrial processes is creating unprecedented opportunities for businesses, employees, and consumers.

Enhanced Operational Agility:

The ability to adapt quickly to changing market demands is a critical advantage. Smart factories equipped with AI and IoT provide real-time insights, enabling manufacturers to pivot efficiently during disruptions or demand surges.

Personalization at Scale:

Additive manufacturing and AI-driven design systems allow industries to offer highly personalized products without compromising efficiency. This customization is particularly impactful in healthcare, automotive, and consumer goods sectors.

Global Competitiveness:

As industries embrace automation and AI, they gain the ability to streamline operations and reduce costs, increasing their competitiveness on a global scale.

Sustainability as a Market Differentiator:

Companies that prioritize eco-friendly practices and sustainable products are capturing the attention of environmentally conscious consumers. This creates a dual benefit of contributing to sustainability goals while driving revenue.

Emerging Business Models:

Innovations like on-demand manufacturing, subscription services for industrial tools, and shared resources in collaborative ecosystems are reshaping traditional business models, opening up new revenue streams.

The convergence of these opportunities positions forward-thinking manufacturers as leaders in a new era of industrial innovation.

Challenges in Adopting Advanced Technologies

While the benefits are clear, the path to fully realizing the potential of advanced industrial technology is not without its challenges:

Cost of Implementation:

Technologies like IoT-enabled systems, AI, and 3D printing require significant capital investment. For small and medium-sized enterprises (SMEs), these upfront costs can be a barrier to entry.

Workforce Transition:

As automation and AI take over repetitive tasks, workers need to transition to roles that require advanced skills in areas like robotics, data analytics, and system programming. This calls for extensive reskilling initiatives.

Cybersecurity Threats:

Increased connectivity through IoT and cloud-based systems also increases the risk of cyberattacks. Industries must prioritize robust cybersecurity measures to protect sensitive data and ensure uninterrupted operations.

Regulatory Compliance:

Governments are imposing stricter regulations related to sustainability, data privacy, and worker safety. Industries need to stay agile to meet these requirements while maintaining efficiency.

Integration Complexities:

Integrating new technologies into existing systems can be challenging, particularly in legacy industries. Ensuring seamless compatibility and avoiding disruptions requires careful planning and execution.

Addressing these challenges is crucial for manufacturers looking to leverage the full potential of emerging technologies.

Emerging Trends and the Road Ahead

As industrial technology continues to evolve, several emerging trends are poised to shape its trajectory:

Autonomous Factories:

Fully autonomous factories, powered by AI and robotics, will become a reality. These factories will require minimal human intervention while delivering high precision and efficiency.

Decentralized Production:

Advances in additive manufacturing are enabling decentralized production models, reducing supply chain complexities and lowering transportation emissions.

Digital Twin Technology:

Digital twins, virtual replicas of physical assets, will become standard tools for simulating and optimizing production processes. This technology will reduce trial-and-error costs and enhance decision-making.

Integration of Smart Materials:

Materials that can adapt to environmental changes or self-heal will open new possibilities in construction, healthcare, and other industries.

Focus on Circular Economy Models:

Industries will increasingly embrace circular economy principles, prioritizing the reuse, recycling, and repurposing of materials to achieve sustainability goals.

These trends highlight a future where industries are smarter, more agile, and deeply aligned with environmental and societal needs.

Why These Advancements Matter

The ongoing shift from traditional automation to intelligent systems driven by AI, IoT, and sustainable practices is more than a technological upgrade—it’s a paradigm shift in how industries operate.

Economic Impact: The adoption of these technologies will boost productivity, create new job opportunities in advanced roles, and drive economic growth.

Environmental Responsibility: Sustainable practices and technologies are setting new standards for responsible production, reducing the environmental footprint of industrial activities.

Global Collaboration: Technology is bridging gaps between industries, enabling global collaboration on innovative projects and creating a more interconnected world.

Conclusion: Embracing the Future of Industrial Technology

From AI-driven automation to additive manufacturing, the advancements in industrial technology are creating a future where industries are more efficient, sustainable, and adaptive. While challenges remain, the opportunities these innovations bring far outweigh the hurdles.

Manufacturers who embrace this transformation will be better positioned to thrive in a rapidly changing global landscape. By investing in cutting-edge technologies, fostering sustainability, and preparing the workforce for future roles, industries can ensure long-term success.

The future of industrial technology is not just about staying competitive—it’s about reshaping the very fabric of manufacturing to meet the demands of an ever-evolving world. Are you ready to be part of this revolution?